addtime:2022-10-12 author:xinyuren hits:233

in recent years, as countries around the world have further reached consensus on carbon reduction goals, china has gradually implemented various measures under the big strategy of carbon peaking and carbon neutralization. at the same time, with the rapid development of the new energy automobile industry and the rapid development of upstream lithium ion battery material enterprises, the market pattern of aluminum plastic composite film for flexible packaging lithium ion battery has changed greatly from 2021-2022. at present, the enterprises that produce aluminum plastic composite films are mainly japanese enterprises represented by dnp and zhaohe, and chinese enterprises represented by zijiang, xinlun, zhuoyue, mingguan, guanglin caiyao, embry, suda huicheng, daoming, andeli, huazheng, huagu, lidun, sweick, etc.

in 2018-2021, european and american new energy vehicles developed rapidly, and korean battery enterprises represented by lg, sk, etc., produced and sold flexible lithium-ion batteries as their main products. as a result, the supply capacity of japanese aluminum plastic composite film enterprises such as dnp, showa, etc. was greatly tested, which greatly weakened the supply capacity of these japanese enterprises to the chinese market. according to incomplete statistics: in 2021, korean battery manufacturers will need about 90 to 120 million square meters of aluminum plastic composite films, dnp can supply about 80 million square meters at full production, and showa can supply about 30 to 400 million square meters at full production. korean battery manufacturers will use a small number of korean local aluminum plastic composite films.

at the same time in china, with the rapid development of new energy vehicles, the demand for soft package lithium ion batteries has grown at a geometric level. many domestic manufacturers of soft package batteries, such as byd, funeng, javert and dofluoro, have vigorously expanded their production, and the growth in demand for aluminum plastic composite films has even exceeded lg, sk and other traditional soft package lithium ion battery enterprises.

under this background, chinese aluminum plastic composite membrane enterprises have made great efforts to expand production, accelerate technology iteration, and strive to catch up with japanese products and compete for the domestic aluminum plastic composite membrane market. at present, there are more than 20 enterprises engaged in the development and industrialization of aluminum plastic composite membrane technology in china, and the production capacity of aluminum plastic composite membrane of domestic enterprises is close to 300 million square meters (including those under planning). it is estimated that by 2025, the global market demand for aluminum plastic composite film will reach 700 million square meters.

according to the analysis of china chemical and physical power industry association on the global market demand for aluminum plastic composite membrane for flexible packaging lithium ion batteries in 2021, the global total demand is about 300 million square meters. in 2021, the sales volume of aluminum plastic composite membrane of chinese enterprises will exceed 100 million square meters, and the market share of domestic aluminum plastic composite membrane enterprises will exceed one third, of which:

shanghai zijiang:

as a high-tech enterprise specializing in special and new technologies, the ministry of industry and information technology is specialized in the r&d and large-scale production of aluminum plastic composite film products, breaking the monopoly pattern of imported products in china's aluminum plastic composite film market. the company's aluminum plastic composite film products can be widely used in 3c digital, power, energy storage and other fields. in 2021, the sales volume will reach 22.18 million square meters, ranking first among domestic enterprises. among them, nearly 60% of power energy storage products.

xinlun technology:

in august 2016, it directly entered the domestic aluminum plastic composite film market through the acquisition of japanese t&t aluminum plastic composite film business. since then, the company has quickly digested and absorbed foreign advanced technology, and independently developed dozens of patents related to aluminum plastic composite film. its complete and comprehensive patent package, advanced customized equipment imported from japan, and unique technical treatment have guaranteed the excellent performance and quality of products, and established the company's position in the industry. in 2021, the sales volume will reach 21 million square meters, ranking the second among domestic enterprises. in 2021, the operating revenue will exceed 520 million yuan, ranking first among domestic enterprises.

excellent:

the new production line has been recognized by high-end consumer customers, power and energy storage customers. the products have successfully entered the above markets and will rapidly increase their share. in 2021, the sales volume will be 11.48 million square meters, mainly digital products.

mingguan new material:

after nearly 10 years of research and development of aluminum plastic composite film and its materials, it has formed an aluminum plastic composite film with independent intellectual property rights, a dry heat preparation process, and its own core technology system of aluminum plastic composite film. in 2021, the sales volume of aluminum plastic composite film will be 5.88 million square meters, of which power energy storage products will account for about 65%.

with the continuous strengthening of the competitiveness of domestic aluminum plastic composite film in recent years, japanese products have gradually withdrawn from the chinese market. dnp, showa and other enterprises have completely abandoned the middle and low-end digital market, and the high-end digital market has also entered the situation of being comprehensively replaced.

from the perspective of the development trend of the industry, the next two years will be the explosive period of localization of aluminum plastic composite film.

source: china chemical and physical power industry association

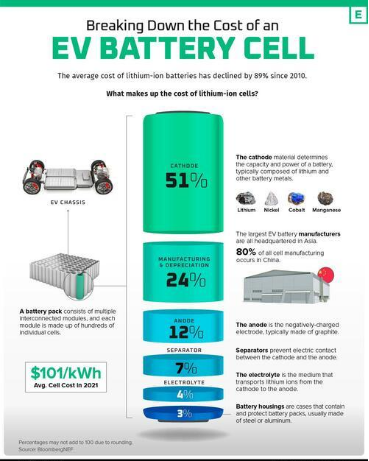

according to the research of govind bhutada of visual capitalist, the research institution, since 2010, the average price of lithium-ion electric vehicle battery pack has dropped from 1200 dollars/kwh to 132 dollars/kwh in 2021.

researchers at the university of texas at austin said that a thicker electrode, through the magnetically optimized ion route, can make charging faster and the power between charging is greater.

according to the research of scotch creek ventures, by 2030, the global demand for lithium-ion electric vehicle (ev) batteries is expected to grow more than 17 times to 9300gwh ten years ago. in order to meet this demand, the global production of lithium-ion batteries for electric vehicles needs to increase rapidly.

> company:0755-84611586

> fax:0755-84611589

> special line:4008855199

> email:xyr@xinyuren.com

> add.:shenzhen longgang district liuzhou street back to hon long bu community peak (longgang) industrial plant no. 2 workshop